rockwell hardness test nomograph|rockwell hardness scale : chain store There are several alternative scales, the most commonly used being the "B" and "C" scales. Both express hardness as an arbitrary See more WEBO Horta Fácil é um programa desenvolvido para horticultores e extensionistas com a finalidade de planejar e manejar uma produção de hortaliças pré-programada e contínua ao longo do tempo. Levando em conta os ciclos fenológicos inerentes a cada espécie hortícola, o software realiza, de forma otimizada, o dimensionamento da área a ser .

{plog:ftitle_list}

22 de dez. de 2023 · Em mais um jogo do torneio italiano Serie A, nesta sexta (22), temos o jogo Empoli x Lazioàs 14h30. A partida acontece no Estádio Carlo Castellani, em Empoli na Itália. Confira palpites, odds, prognósticos e outros dados para melhorar seu palpite. Tá na hora de levar green comEmpoli x Lazio!

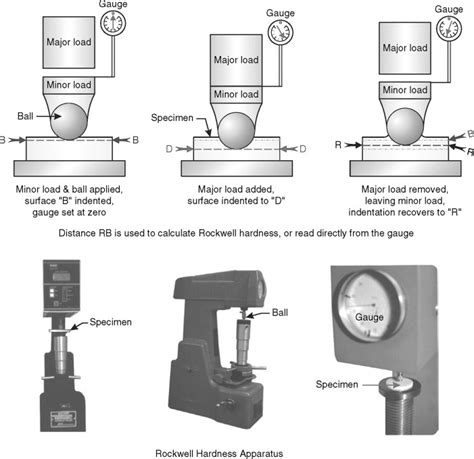

The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). There are different scales, denoted by a single letter, that use different . See moreThe differential depth hardness measurement was conceived in 1908 by Viennese professor Paul Ludwik in his book Die Kegelprobe (crudely, "the cone test"). The differential-depth method . See moreThe Rockwell hardness test can be conducted on several various hardness testers. All testers, however, fall under one of three categories. Bench model hardness testers can be found . See moreThere are several alternative scales, the most commonly used being the "B" and "C" scales. Both express hardness as an arbitrary See more

• International (ISO)• US standard (ASTM International) See more

• Brinell hardness test• Hardness comparison• Holger F. Struer• Knoop hardness test See more

• Video on the Rockwell hardness test• Hardness Conversion Chart• Rockwell to brinell conversion chart• Hardness Conversion Table See more The purpose of this Guide is to explain the causes of variability in Rockwell hardness test results and to supplenment the information given in test method standards with .

Rockwell Hardness Testing Reference Guide. ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your .The Rockwell test is based on measurement of the depth of penetration with the hardness number read directly from the dial gauge or digital display that is part of every tester. In .International Standards Organization – Rockwell Hardness Test Part 1 – Test Method (ISO 6508-1 Metallic Materials) The reason all steel product manufacturers use the Rockwell hardness scale is that it allows uniformity in .

Rockwell Hardness Testing Reference Guide ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your .Portable Rockwell hardness testers are available, which allow for on-site or field hardness testing. This is advanta-geous for applications where it is not feasible to transport samples to a laboratory or for situations that require imme-diate hardness assessment. Portable Testing 1.1Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most commonly used low-load method is Vickers. Low-load hardness testing is mainly used for testing of small .What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared to other methods, like Vickers or Brinell hardness testing. Another advantage is the small area of indentation needed to carry out the .

D ue to the simplicity of the experiment and the possibility of in-service inspection, the instrumented indentation technique is being increasingly used to study the mechanical properties (e.g., hardness and tensile properties) of films, coatings, and small-volume materials.[1,2,3,4,5,6,7,8,9,10,11] However, though different hardnesses (e.g., Brinell . The Rockwell hardness test involves making an indentation on the test material. The indenter is either a conical diamond or a steel ball. Indenter ball diameters range from 1/16 to 1/2 inches and are chosen based on the test parameters.

Indenters in a Rockwell hardness test are either hardened steel balls or a conical diamond. Two sets of loads cause an impact on the material surface, which include an initial minor load and a final major load. Additionally, the impact often causes an indentation on the material surface, and measuring the depth of this indentation helps to .

Rockwell hardness test is applied with the carbide balls to test softer materials such as construction steels or brass because if you test soft material with diamond cones, it could cause very deep penetration into the material which will go far outside from the specified depth of 0.2mm. With a carbide ball, the specified reference depth is .

The rockwell hardness test is commonly used to measure the hardness of steel, which is crucial for kitchen knives. Knives with higher rockwell hardness scores are generally tougher and more resistant to wear and tear. On the other hand, blades with lower hardness scores may be more flexible and less prone to chipping. .Load: The Rockwell hardness test uses a pre-load of 10 kgf, followed by the application of the main load, which varies depending on the Rockwell scale being used (e.g., 60 kgf for the Rockwell A scale, 150 kgf for the Rockwell C scale). The load is applied for a .

08 honda civic si compression test numbers

ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for metallic materials. ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness . Rockwell Hardness Test. The Rockwell hardness test is a widely used method for determining material hardness, especially in high-volume testing environments, due to its speed, simplicity, and efficiency. It provides direct hardness readings without the need for additional calculations, making it ideal for routine quality control.

The concept of the Rockwell Hardness test is essentially similar to its counterparts. A sample material is fed on to either a digital or manual Rockwell hardness tester which would then drop a set load ending with an indenter on the surface. Then, the strength of the material will be determined by the nature of the indentation left on the sample. Rockwell hardness testing can determine the hardness of most metals, alloys and plastics, ranging from the softest bearing materials to the hardest steels. Photo: Wilson Instruments, An Instron Company. Stanley P. .Rockwell hardness test into what is today the most widely used method for acceptance testing and process control of metals and metal products. Since its development, the popularity of the Rockwell hardness test has steadily grown. The Rockwell hardness test continues to be applied as a tool for The equation for the Rockwell hardness test for metals is below: d=depth from zero load point. N and s = various scale factors that can be found in the chart below. Rockwell A scale. Used to test: Tungsten carbide. Rockwell .

In the Rockwell hardness test, the measure of the hardness is not an indentation surface but an indentation depth. Either a carbide ball or a rounded diamond cone with a tip angle of 120° and a tip radius of 0.2 mm serves as the indenter. The indentation depth can be read directly from a dial gauge via the traverse path of the testing machine.Before a Rockwell hardness testing machine is verified, the machine shall be checked to ensure that it is properly set up in accordance with the manufacturer's instructions: Especially it should be checked that: a) the plunger holding the indenter is capable of sliding in its guide; The Rockwell hardness test continues to be applied as a tool for assessing the properites of a product while the tolerances on the acceptable material hardness have become tighter and tighter. Adhering to good practice procedures when performing Rockwell hardness measurements and calibrations is a beneficial step to reducing measurement errors.

Rockwell Hardness Scale. The Rockwell Hardness Scales comprise various types, depending on the material to be tested. Each scale utilizes different loads or indenters, and permits the testing of materials with different hardness. For instance, the HRB scale is employed for testing soft steels, aluminium, and brass, and involves applying minor .

rockwell hardness testing procedure

The test procedure for the Rockwell hardness test is covered in the standard document ISO 6508 for metallic materials and ISO 2039-2 for plastics. The overall procedure is similar to other indentation tests. The indenter is pressed into the material, loaded for a time interval (dwell time), and unloaded. .II. Theory and Principle of the Rockwell Hardness Test. The Rockwell Hardness Test uses a depth-differential method to test for hardness. A predetermined minor load is applied to the test sample, and the depth measurement is taken. Then a major load is applied to the same spot, which creates a deeper indentation.Hardness scales Hardness according to Rockwell (HRc - cone and HRb - ball) The depth of penetration of an indenter is measured by loading a certain force. Either a ball (HRb) or cone (HRc) can be used. It is a quick and simple measurement, especially suitable for cutlery steels. Vickers hardness test (HV) A pyramidal diamond indenter with a 136 .

09 crf.450 compression test

1. Define Hardness. 2. Applications of Rockwell Hardness A ± Scale, B-Scale, C-Scale. 3. Type of Indentor used in the Three Different Scales of Rockwell Hardness Test. 4. Different Types of Hardness Testing Methods. 5. Size of the Ball to be used in Ball Indentor of Rockwell Hardness Test. 6. Di ameters of the different Balls used in Brinell .

The Rockwell hardness test method is a simple process that uses a diamond cone with a round tip for harder materials and a hardened steel ball indenter for softer ones. With every test, two loads are applied to the test subject. First, an indenter is forced into the test subject under an initial load of 10kg-f, and the depth is recorded. It should be added that the conducted tests are a direct response to the existing provisions of the current European standards, which concern measurements of hardness using the Brinell method EN ISO 6506–1:2014 [5], as well as the Vickers and Rockwell methods: „It is not possible to accurately convert hardness into other hardness or tensile .

1 2 inch reach compression tester

1 cmc compression test

1.3 l rotary compression test

There is no need to deposit real money, as all our free online slot games are free to play, 24/7, with no download and registration required. We take pride in offering the catalog of 7777+ free slot machines online, and we expand our selection daily to provide users with a complete and freshly updated database of games.

rockwell hardness test nomograph|rockwell hardness scale